HIGH OR LOW VOLUME?

NO PROBLEM!

Our modern flexible manufacturing processes allow us to supply high volume to low volume that meets our customer requirements. We work with many OEM manufacturers that demand high quality and competitive pricing. We welcome new customer inquiries from anywhere within the U.S. and abroad.

Low Cost

Provider

We are an integrated supplier of zinc die castings, machining, polishing and buffing, and decorative chrome plating. Therefore, we have the ability to offer more competitive pricing versus our competition that must ship your parts to multiple suppliers in multiple locations in order to provide the same end product.

Quickest Turn-

around Time

Because we complete everything in-house, our turnaround time is much faster than our competition. Our lead time from engineering to first part approval is the quickest in the industry. Please contact us and let us know your requirements.

Easier Approval

Process

When our prospective clients visit our facility, they are extremely happy that they only need to visit our building in order to offer their full approval. Most of our competitors would force you to visit multiple locations operated by different companies where all of the processes are completed.

Building Long Term Relationships

Our customers remain loyal because we ensure everything from quoting to delivery is a trouble-free process.

We offer:

- Consistent quality, service, and value.

- Convenience of working with a completely integrated manufacturer.

- Continuous improvement and lean initiatives ensure superior quality, value & shortest lead times.

- Precise manufacturing controls to meet your exact specifications.

- Experience with a variety of worldwide customers including many OEM manufacturers.

- Ability to process short run as well as high run production volumes.

QMF zinc die casting quality goes well beyond the usual definitions. We start with only those materials which meet your zinc alloy specifications.

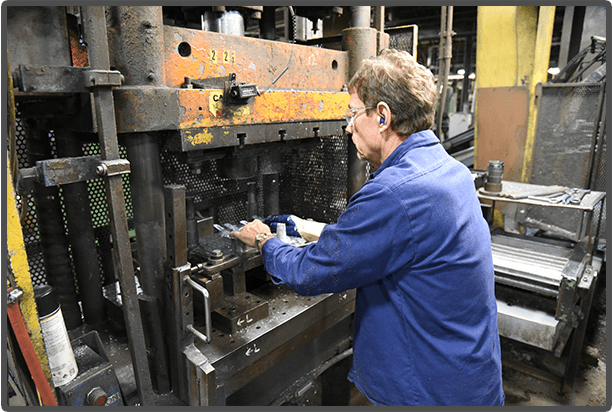

Customized tooling is designed and built to provide a top quality zinc die casting that results in the strength and metal surface finish you require.

Quality auditing throughout the entire production process includes detailed checking of zinc die castings prior to trimming plus on-going audits at all secondary operations such as drilling, tapping, and machining. We designed the process to yield the highest quality product.

Our integrated process allows us to finish and plate products within hours of producing a die casting. This is a distinct advantage when producing castings for decorative finish and one that validates the process controls utilized in die cast.

- Clean removal of flashing

- Certified virgin alloys

- Various machining operations to meet customer specifications

- Superior surface finish zinc die castings to compliment the needs of decorative chrome plating.

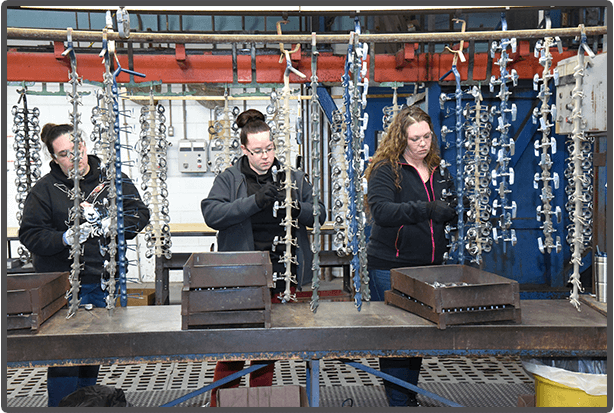

Vital to any decorative plating system is the metal finishing process. Using a unique blend of metal polishing plus hand, semi-automatic, as well as automatic metal buffing machinery developed by our engineers, our highly skilled employees produce millions of components annually.

Each finished metal piece has a signature QMF-quality part surface that is destined for beautiful results in metal plating. Special care is taken at each step, with a close examination of potential problem areas such as parting lines, concealed surfaces, and other part features. Finished parts are appropriately protected with trays or divided containers.

- Invisible parting lines

- Consistent brushing

- Smooth finish, even in hard to reach areas

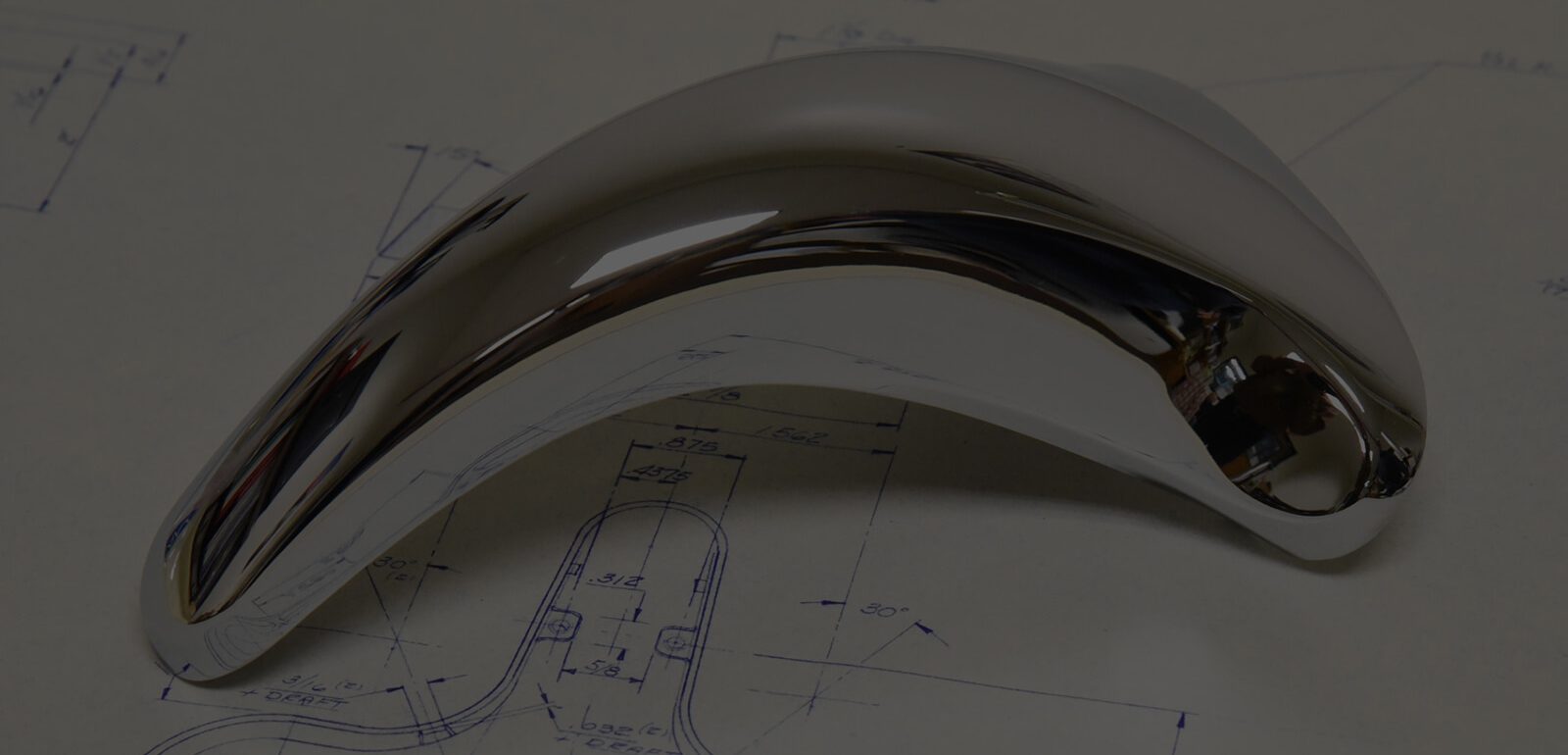

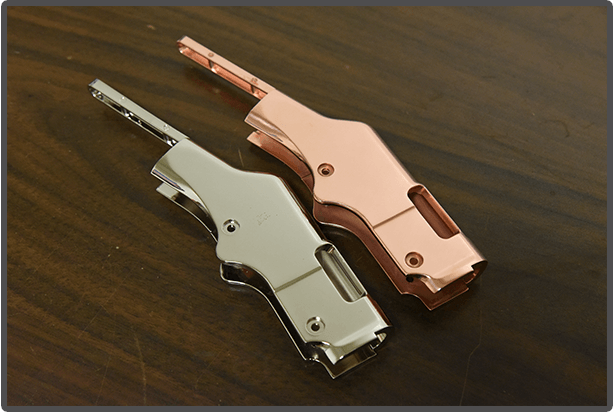

Whether you are choosing QMF for all three of our integrated services or metal plating only, you can depend upon our expertise in supplying bright chrome and other metal finishes which meet the toughest industry and customer standards.

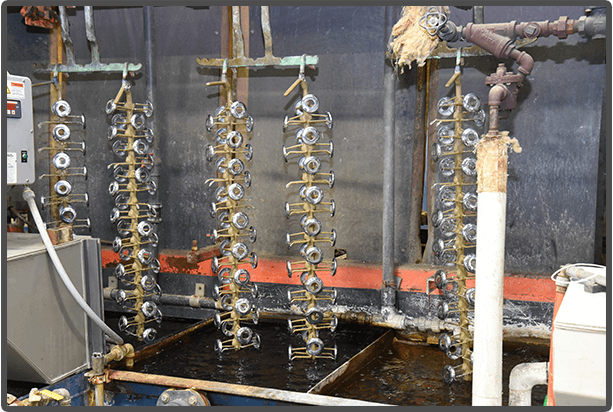

A visit to our plant shows one of the nation’s largest automated copper, nickel, chrome rack plating lines.

In addition to bright chrome on die cast zinc, we offer brushed nickel and satin chrome finishes which are popular in many home décor products, plus specialty plating of brass.

Bright Chrome

- Bright color and luster

- Smooth surfaces

- Blemish free metal plating

Brushed Nickel

- Uniform brushing lines

- Consistent metal plating thickness